-

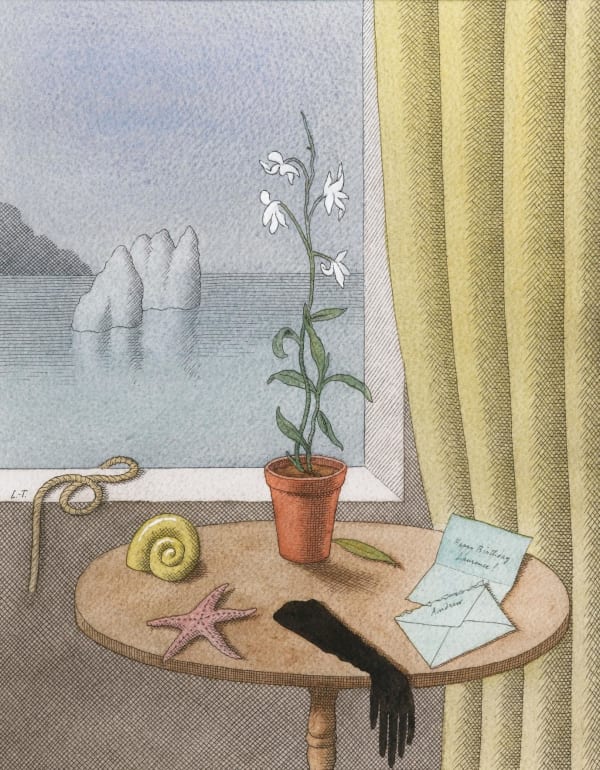

Pierre Le-Tan

-

Taizo Kuroda

-

Alessandro Twombly

-

Nicolas Lefebvre

-

Malick Sidibé

-

Ritsue Mishima

-

Sydney Albertini

-

Kaori Tatebayashi

-

Peter Schlesinger

-

Dominique Lacloche

-

Sussy Cazalet

-

Alejandro Guijarro

-

Christabel MacGreevy

-

Seydou Keïta

-

Flavie Audi

-

Yves Marchand & Romain Meffre

-

Mick Cooper

-

Parme Baratier

-

Tristano di Robilant

-

Maryam Eisler

-

Rafaela De Ascanio

-

J.D. Ojeikere

-

Orsina Sforza